Do you startle awake in the middle of the night to the sound of a heavy truck horn shaking your windows? Is the voice of the street vendor with his microphone an inseparable part of your morning routine? Do you have to turn the TV volume up to the max just to hear the dialogue over the constant background drone of the street?

If your answer is yes, you are not alone. Unfortunately, noise pollution in Egypt—especially in crowded cities—is no longer just a passing annoyance; it has turned into a daily health crisis. Recent studies confirm that continuous exposure to high noise levels is a direct cause of elevated stress, chronic sleep disorders, lack of focus, and even high blood pressure. Your home should be your quiet sanctuary, not an extension of the street noise.

The Common Misconception: “Just Install Double Glazing”

Many clients believe the magic solution lies in one phrase: “I’ll install double glazing.” The client goes to a traditional workshop, asks for a double-glazed window, and returns home to discover that the noise level has dropped only slightly—nowhere near the value of the money spent—and annoying sounds still pierce through the room.

The surprise we tell you here as engineering specialists: Double glazing alone, if installed on a standard aluminum frame, will not solve the noise problem in Egypt by 100%, or even 60%.

Why? Because soundproofing is not a single “piece” you buy; it is an “Integrated System.” A chain is only as strong as its weakest link, and in a traditional window, there are many weak links that leak sound.

In 2026, construction technology has evolved amazingly, and UPVC has become the undisputed master of this system. Let us take you on a deep engineering tour to explain how we transform your room into a quiet studio.

Why Does the Standard Aluminum Window Fail? (Diagnosing the Problem)

To understand the solution, we must first understand the problem. Sound is energy waves traveling through a medium (like air) and through solid objects (as vibrations). The traditional window fails to block these waves for two fundamental reasons:

1. Air Leakage: The golden rule of soundproofing is: “Where air passes, sound passes.” Any gap, even the width of a “hair” between the moving sash and the fixed frame, or at the corner joints (which rely on screws), is a wide-open gate for sound waves. Traditional aluminum windows, especially the “Sliding” systems, rely on “brush seals” (mohair strips) for insulation. By nature, these brushes do not achieve a complete seal. Over time, combined with Egypt’s dust, they wear out and become useless, creating direct pathways for noise to enter.

2. Vibration & Resonance: Aluminum is a relatively lightweight metal and a very good conductor of vibrations. When strong sound waves (like a diesel engine or a loud microphone) hit the facade, the aluminum frame itself vibrates, transmitting these tremors directly inside the room, acting almost like an “Amplifier” for the noise rather than an insulator.

How UPVC Achieves “Silence” (The Engineering Equation)

At [Your Company Name], we do not treat a window as a product sold by the meter, but as a 3-dimensional engineering equation for sound isolation. To reach a satisfactory and real result, all three sides of the triangle must be completed with precision:

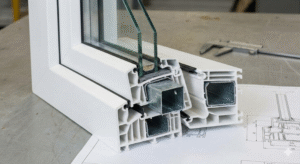

Side 1: The Profile – The Sound Trap (The Multi-Chamber Profile)

The UPVC profile is radically different from metal. First, the UPVC material itself (treated Vinyl) is “acoustically inert,” meaning it does not ring or transmit vibrations easily like metal. Second, and most importantly, the profile is not solid or empty inside; it is geometrically divided into multiple consecutive “Chambers” (usually 3, 4, or even 5 and 6 chambers in advanced 2026 systems). How do they work? They act as successive traps for sound waves. When the wave penetrates the first wall of the profile, it enters the first air chamber and loses some of its energy, then hits the second wall, loses more, and so on. The more chambers and the deeper the profile, the more it disperses and weakens noise before it crosses inside.

Side 2: The Sealing System – The Secret of “Airtightness”

This is the most critical secret many overlook. In professional UPVC systems, we do not use “brushes” to stop dust and sound. We rely on high-quality EPDM Gaskets (the same durable, flexible material used in refrigerator and car door seals, known for extreme longevity and weather resistance). When you close a UPVC window, thanks to the smart accessory design, this rubber is “compressed” tightly between the sash and the frame, creating a complete “Airtight Seal.” Since we have completely stopped airflow, we have cut off the main highway for sound waves.

Side 3: The Glass Unit – “The Science of Glazing”

Here lies the real difference between traditional work and acoustic engineering. Standard double glass (e.g., 6mm glass + 6mm air gap + 6mm glass) is a good start, but it is effective only with medium and high frequencies (like birds or normal speech). It often fails against deep, low-frequency street noise (diesel engines, heavy transport). For professional soundproofing in busy areas, we use advanced techniques:

-

Wider Spacer: Increasing the distance between glass panes (using 12mm, 16mm, or 20mm gaps instead of 6mm) increases efficiency in breaking sound waves.

-

Asymmetric Glazing: A smart physics trick. If we use two panes of the same thickness (6+6), they vibrate at the same frequency (a weakness called resonance frequency). The solution is using different thicknesses (e.g., 8mm outer + air gap + 6mm inner). This difference forces each pane to block different frequencies, confusing the sound wave and breaking it much more effectively.

-

Laminated Glass: The ultimate solution for extreme cases (living on a ring road, highway, or noisy commercial area). It consists of two layers of glass bonded together by a transparent, flexible, and very strong plastic film (PVB) in the middle (similar to a car windshield). This film acts as an acoustic damper, killing vibrations dead before they transmit inside. A combination like (Laminated outer + large air gap + asymmetric inner) is the pinnacle of soundproofing technology in 2026.

Final and Crucial Advice Before You Buy

The Opening Type affects the final sound insulation efficiency by at least 40%.

If your top priority is total silence, we always advise avoiding the “Sliding” system, because its movement on wheels requires a slight clearance to move, relying on brushes that leak sound. The optimal and strongest choice for soundproofing is the “Casement” (Turn) or the dual “Tilt & Turn” system. Why? Because its closing method relies on Compression. When you turn the handle, the internal metal hardware pulls the sash and compresses it with extreme force against the EPDM gaskets on the frame from all sides, achieving the highest possible tightness.

Invest in your mental health, your peaceful sleep, and your children’s focus. Silence in your home is not a luxury; it is a necessity for a healthy life. Let us at [Your Company Name] accurately assess the noise level in your area and design the UPVC system (profile type, gasket system, and optimal glass composition) that perfectly fits your needs and budget, so you can reclaim your lost peace of mind.